Maximum Performance Under Extreme Conditions

Power electronics are the backbone of modern energy converters, e-mobility, and industrial applications. Miniaturization and high performance require absolute reliability of every material connection—from the contact surface to the final encapsulation. Voids, oxides, and material mismatches become critical risk factors.

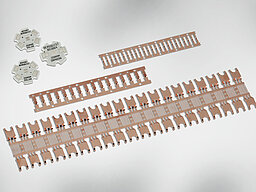

Power modules—the heart of modern power electronics

Power modules are the backbone of modern electronic power conversion across e-mobility, industrial applications, and renewable energy systems. They handle extreme currents while demanding maximum miniaturization and sophisticated thermal management. With the use of advanced materials such as SiC and MOSFET technologies, designs are becoming ever more compact and efficient.

However, this technological progress also introduces significant challenges. Voids and oxide layers can severely reduce performance and shorten service life. The ongoing trend toward miniaturization requires utmost precision, as even the smallest inaccuracies can have a measurable impact. At the same time, thermal stress, complex material transitions, and continuous vibration place additional strain on the components. Together, these factors increase the risk of failures, delamination, and customer complaints — ultimately threatening both product reputation and warranty reliability.

Extreme demands on materials and connections

High-performance power modules must deliver reliable operation for years under extreme conditions—in electric vehicles, wind turbines, or industrial drives. High temperatures, voltages, and mechanical stresses coincide with increasingly compact designs. A major challenge arises at so-called “triple points,” where materials like copper, ceramics, and potting compounds meet. These zones are prone to stress, voids, and adhesion issues that can drastically reduce service life. Oxidized metal surfaces further impair solderability and raise contact resistance, while overmolding increases the risk of epoxy delamination.

The solution lies in reliable interconnect technologies and precise surface treatment to ensure long-term stability.

Our solution for typical power pain points

Comparison with competitive processes—Why Plasmatreat is superior

Other cleaning processes such as wet chemistry, vacuum procedures, or mechanical methods face key limitations. Wet chemical cleaning removes thick oxide layers but needs chemicals, complex rinsing steps, and causes environmental pollution. Vacuum processes are mostly batch operations, use a lot of energy, and are difficult to automate. Mechanical techniques like brushing risk leaving particles and aren't reliable for inline quality.

Plasmatreat sets new standards: Openair-Plasma® and REDOX® tools deliver fully automated, physical, chemical-free cleaning in-line that outperforms conventional processes. These methods reliably remove even tough oxide layers, prepare large or complex parts, and, with PlasmaPlus®, form a protective nano-barrier against moisture, migration, and aging.

Plasmatreat offers maximum process integration, scalability, and sustainability—without compromise.

Customer benefits at a glance

Maximum electrical conductivity, fewer errors and failures

The targeted removal of oxide layers with the REDOX®-Tool creates flawless metallic contact surfaces – particularly important for high-current modules and IGBTs. Additional plasma activation and nano-coating ensure secure, long-lasting connections during sintering and casting. This reduces delamination, maximizes conductivity, and ensures long-term reliability.

Reliable operation under extreme loads

Whether high temperatures in the sintering process or continuous mechanical stress in the field: Openair-Plasma® surface treatment prevents adhesion problems, minimizes voids and cracks, and ensures consistent performance – even in the most demanding automotive, industrial, and energy applications.

Lower warranty costs and longer service life

Defects such as voids and adhesion problems are minimized right from the production process. This increases the reliability of the modules, reduces complaints and rework, and extends service life – particularly relevant for industries with the highest quality standards.

Sustainable, environmentally friendly manufacturing

Plasmatreat deliberately relies on physical processes and avoids aggressive chemicals and fluxes. This saves resources, reduces the ecological footprint, and makes production safe and sustainable.

Maximum cost efficiency through automated inline processes

With Openair-Plasma® technology, surfaces can be treated automatically and continuously directly in the production flow—without downtime or manual reworking. This means consistently high quality, fast throughput times, and sustainably reduced unit costs. Less waste, higher yields, and minimal consumption of consumables lead to noticeable cost reductions.

Inline oxide removal at the highest level

For the most demanding requirements in electrical contacts, bonding, and reliability in power modules, the REDOX®-Tool combines nitrogen and hydrogen in a tunnel process for the complete removal of oxide layers – fully automatically, inline, and without chemicals.

Learn more about the REDOX®-Tool

Our solution: Precise surface treatment for reliable power modules

Plasmatreat’s Openair-Plasma® technology and the REDOX®-Tool provide advanced inline cleaning and oxide reduction that ensure optimal adhesion and reliable performance—even for demanding applications.

Oxide layers and weak adhesion are thoroughly eliminated, resulting in clean, defect-free surfaces.This leads to improved conductivity for power modules and semiconductors, higher yield rates, and less rework due to consistently clean processes. Durable adhesion and material compatibility maximize product reliability and service life, especially under tough conditions. With Plasmatreat, manufacturers can count on best-in-class results for next-generation high-performance electronics—delivering superior electrical properties and long-lasting quality.